Back

Present

Facts for Kids

Phenolic resin is a synthetic polymer known for its excellent thermal stability, chemical resistance, and versatility in various industrial applications.

Explore the internet with AstroSafe

Search safely, manage screen time, and remove ads and inappropriate content with the AstroSafe Browser.

Download

Inside this Article

Chemical Reaction

Leo Baekeland

Electronics

Production

Technology

Building

Bakelite

Good

Are

Did you know?

🛠️ Phenolic resin is known for its high thermal stability and resistance to heat and chemicals.

🔬 It was first developed by chemist Leo Baekeland in the early 20th century.

🏗️ Often used in the manufacturing of molded products, such as electrical insulators and industrial goods.

🎨 Phenolic resin can be formulated into various colors and finishes, making it versatile for aesthetic applications.

♻️ It is commonly used in composite materials due to its excellent mechanical properties.

💡 Phenolic resin's electrical insulating properties make it ideal for electronic components.

🌱 Some phenolic resins are produced using bio-based materials, enhancing their sustainability.

🧪 The curing process of phenolic resin involves heat and pressure, leading to a hard and inflexible final product.

🛡️ It is resistant to moisture, which makes it suitable for environments with high humidity.

📦 Phenolic resin is widely used in laminates, such as countertops and flooring.

Show Less

Become a Creator with DIY.org

A safe online space featuring over 5,000 challenges to create, explore and learn in.

Learn more

Overview

Phenolic resin is a special kind of plastic made from a substance called phenol. 🧪

It was invented in 1907 by a scientist named Leo Baekeland. Phenolic resins are strong, heat-resistant, and can be made into many shapes! 🌟

They are used in products like electrical insulators, kitchenware, and even car parts. Did you know that these materials are lightweight yet very durable? They can be found all over the world, from factories to homes! 🌍

Phenolic resins help make our daily lives better by providing reliable and sturdy products.

It was invented in 1907 by a scientist named Leo Baekeland. Phenolic resins are strong, heat-resistant, and can be made into many shapes! 🌟

They are used in products like electrical insulators, kitchenware, and even car parts. Did you know that these materials are lightweight yet very durable? They can be found all over the world, from factories to homes! 🌍

Phenolic resins help make our daily lives better by providing reliable and sturdy products.

Read Less

Uses in Industry

Many industries use phenolic resins because they are so reliable! 🚗

In the automotive industry, they help create strong parts for cars and trucks. In construction, they are used for making durable flooring and countertops. 🏠

In electronics, they act as electrical insulators, protecting wires and components. 🌐

Even in the aerospace industry, phenolic resins are used to make lightweight parts! Their toughness and heat resistance make them perfect for demanding jobs. This means that whenever you see a car, building, or device, phenolic resin might be playing a role!

In the automotive industry, they help create strong parts for cars and trucks. In construction, they are used for making durable flooring and countertops. 🏠

In electronics, they act as electrical insulators, protecting wires and components. 🌐

Even in the aerospace industry, phenolic resins are used to make lightweight parts! Their toughness and heat resistance make them perfect for demanding jobs. This means that whenever you see a car, building, or device, phenolic resin might be playing a role!

Read Less

Environmental Impact

The production of phenolic resins can impact the environment. 🌳

Chemicals used in the process could potentially harm nature if not handled with care. However, scientists are working to make the production cleaner and safer! 🧹

Some companies recycle used phenolic products or create new methods to reduce pollution. 🌱

Using these materials helps to preserve natural resources since they can last a long time. It's important for companies to be responsible while making valuable products like phenolic resins to keep our planet safe and healthy! 🌎

Chemicals used in the process could potentially harm nature if not handled with care. However, scientists are working to make the production cleaner and safer! 🧹

Some companies recycle used phenolic products or create new methods to reduce pollution. 🌱

Using these materials helps to preserve natural resources since they can last a long time. It's important for companies to be responsible while making valuable products like phenolic resins to keep our planet safe and healthy! 🌎

Read Less

Manufacturing Process

Making phenolic resin is like following a special recipe! 🥳

First, phenol and formaldehyde are mixed together in a big pot, and heat is applied. This causes a chemical reaction, making a thick, gooey substance called a prepolymer. 🌡

️ Next, this prepolymer is put into molds to create different shapes like boards or parts for toys. After that, the shapes are cooked, solidifying them into hard materials. 🛠

️ Finally, they are cooled and often sanded or finished for a polished look. This whole process ensures that each phenolic resin item is strong and ready for use!

First, phenol and formaldehyde are mixed together in a big pot, and heat is applied. This causes a chemical reaction, making a thick, gooey substance called a prepolymer. 🌡

️ Next, this prepolymer is put into molds to create different shapes like boards or parts for toys. After that, the shapes are cooked, solidifying them into hard materials. 🛠

️ Finally, they are cooled and often sanded or finished for a polished look. This whole process ensures that each phenolic resin item is strong and ready for use!

Read Less

History of Phenolic Resins

The journey of phenolic resins began over a century ago! 🚀

In 1907, Leo Baekeland created the first synthetic resin while trying to find a way to make an electric insulator. By mixing phenol with formaldehyde, he invented Bakelite, the first truly synthetic plastic. 🎨

As time went on, people discovered how useful these materials could be! By the 1930s, they were being used in everything from radios to kitchen countertops. 🏠

Today, phenolic resins are still popular and are used in many different kinds of products around the world!

In 1907, Leo Baekeland created the first synthetic resin while trying to find a way to make an electric insulator. By mixing phenol with formaldehyde, he invented Bakelite, the first truly synthetic plastic. 🎨

As time went on, people discovered how useful these materials could be! By the 1930s, they were being used in everything from radios to kitchen countertops. 🏠

Today, phenolic resins are still popular and are used in many different kinds of products around the world!

Read Less

Properties and Applications

Phenolic resins have unique properties that make them special! 🌟

They resist heat, which means they won't melt easily, making them great for things like kitchenware. They are also resistant to chemicals, so they won’t break down when they come in contact with cleaners or other substances. ✨

This makes them useful in furniture, cars, and electrical appliances. Plus, they can be made in many colors and styles! 🎨

Because of all these properties, phenolic resins are key materials in industries like construction, automotive, and electronics.

They resist heat, which means they won't melt easily, making them great for things like kitchenware. They are also resistant to chemicals, so they won’t break down when they come in contact with cleaners or other substances. ✨

This makes them useful in furniture, cars, and electrical appliances. Plus, they can be made in many colors and styles! 🎨

Because of all these properties, phenolic resins are key materials in industries like construction, automotive, and electronics.

Read Less

Health and Safety Considerations

Safety is very important when working with phenolic resins! 🦺

Some chemicals in the production process can be dangerous if inhaled or touched. That’s why workers wear protective gear like gloves and masks to stay safe. 😷

It’s also crucial to use these materials safely at home, especially in kitchen items. If things are burned or heated too much, they can release smoke that might not be good for us. 🔥

Always remember to follow safety rules! By keeping ourselves and the environment in mind, we can enjoy the benefits of phenolic resins without harm!

Some chemicals in the production process can be dangerous if inhaled or touched. That’s why workers wear protective gear like gloves and masks to stay safe. 😷

It’s also crucial to use these materials safely at home, especially in kitchen items. If things are burned or heated too much, they can release smoke that might not be good for us. 🔥

Always remember to follow safety rules! By keeping ourselves and the environment in mind, we can enjoy the benefits of phenolic resins without harm!

Read Less

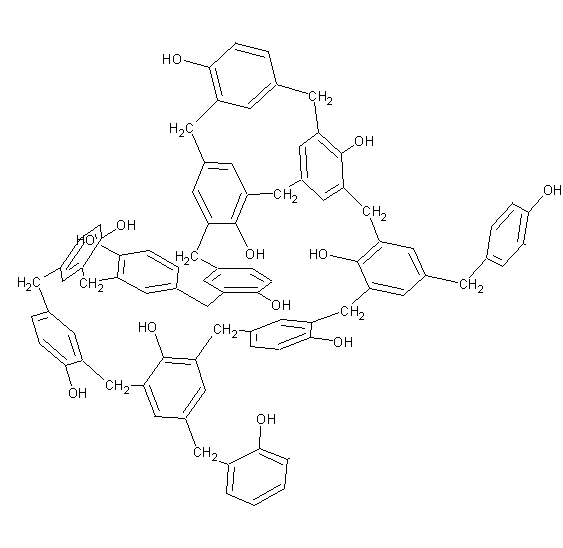

Chemical Composition and Structure

Phenolic resins are made up of tiny building blocks called molecules. 🧬

The main ingredient is phenol, which comes from coal or oil. When phenol joins with formaldehyde, it creates a chain-like structure called a polymer. 🛠

️ This polymer gives phenolic resins their special properties! They can be shaped when heated and harden as they cool. Scientists study these structures to understand how they work and improve their products. 🔍

Phenolic resins can also be combined with other materials to create even stronger or more flexible items!

The main ingredient is phenol, which comes from coal or oil. When phenol joins with formaldehyde, it creates a chain-like structure called a polymer. 🛠

️ This polymer gives phenolic resins their special properties! They can be shaped when heated and harden as they cool. Scientists study these structures to understand how they work and improve their products. 🔍

Phenolic resins can also be combined with other materials to create even stronger or more flexible items!

Read Less

Future Developments in Phenolic Resins

The future of phenolic resins looks bright! 🌈

Scientists are always searching for new ways to improve these materials. They are working on making them even more eco-friendly and efficient to produce. 🌱

Some researchers are exploring using plant-based ingredients instead of oil to create more sustainable versions! This could help reduce pollution and conserve natural resources. 🚀

Also, advancements in technology may lead to even stronger and lighter phenolic resins, opening up new possibilities in various industries. Who knows what amazing products we’ll see next?

Scientists are always searching for new ways to improve these materials. They are working on making them even more eco-friendly and efficient to produce. 🌱

Some researchers are exploring using plant-based ingredients instead of oil to create more sustainable versions! This could help reduce pollution and conserve natural resources. 🚀

Also, advancements in technology may lead to even stronger and lighter phenolic resins, opening up new possibilities in various industries. Who knows what amazing products we’ll see next?

Read Less

Try your luck with the Phenolic Resin Quiz.

Try this Phenolic Resin quiz and see how many you score!

Q1

Question 1 of 10

Next

Explore More